IMTS recap: a successful event

MachiningCloud is excited to share the incredible success of our participation in IMTS 2024! The event was a success, filled with valuable connections, positive feedback, and promising opportunities.

MachiningCloud is excited to share the incredible success of our participation in IMTS 2024! The event was a success, filled with valuable connections, positive feedback, and promising opportunities.

Product Data Enhancements September 2024 monthly data update Bug Fixes Fixed issue with missing F&S for Mitsubishi turning CUT label

Product Data Enhancements August 2024 monthly data update User upload Adjusted STP reader to support Sandvik Coromant STP in user

Product Data Enhancements July 2024 monthly data update UI Show item count in the different tabs in the Job Users

Product Data Enhancements June 2024 monthly data update Feeds and Speed API (contact us for help or information) Our Feeds

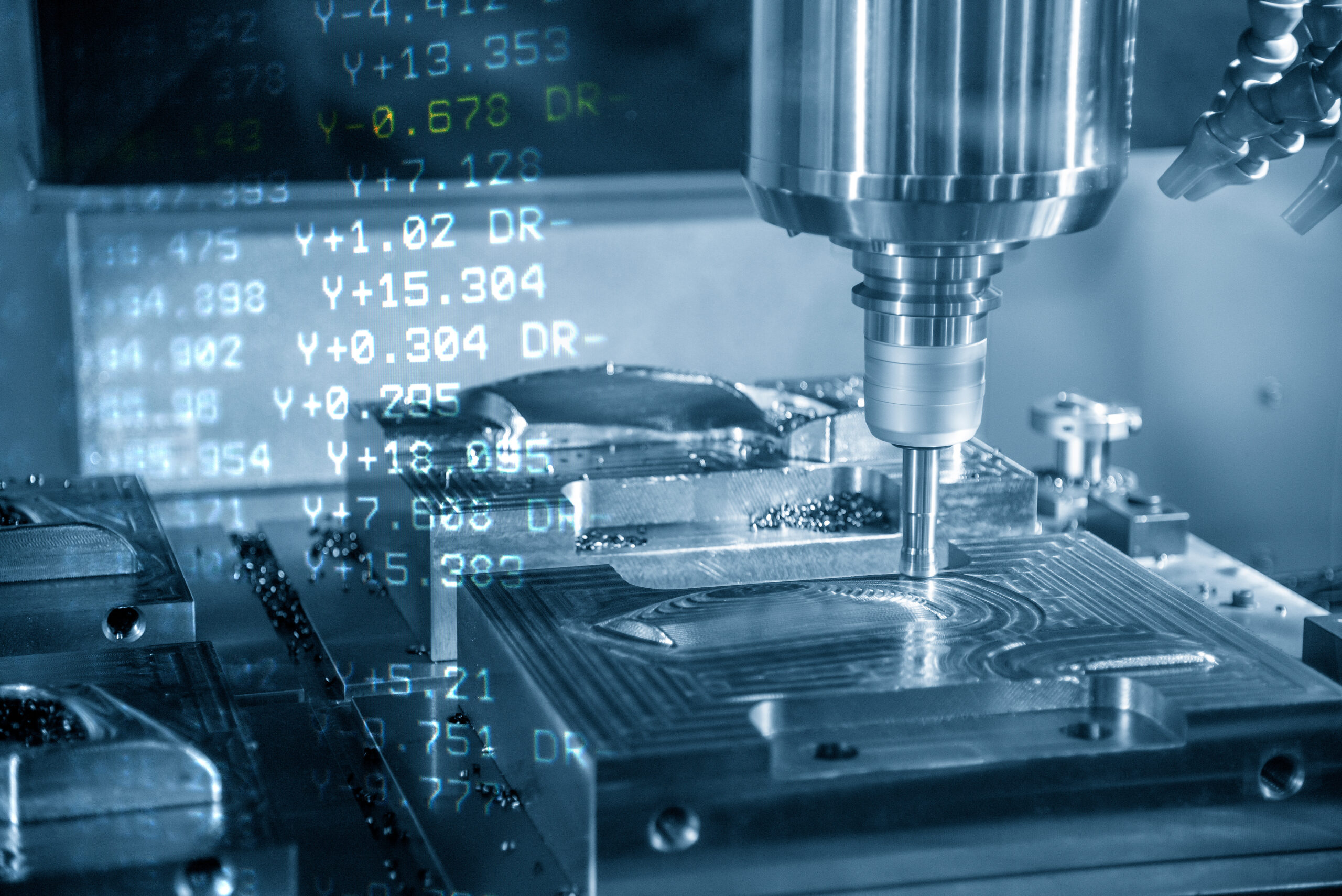

The hum of machinery and the scent of oil are hallmarks of a busy machine shop. But in today’s digital age, reliance on paper trails and siloed information is a recipe for inefficiency. Machine shops that don’t embrace digitization risk falling behind.

Traditionally, data resided in blueprints, handwritten notes, and scattered spreadsheets. This fragmented approach makes it difficult to track progress, identify bottlenecks, and optimize workflows. The future of machining is electronic.

Product Data Enhancements MAY 2024 monthly data update User Upload UI improvements Fusion Export Property and tool type

In the world of manufacturing, inventory management is a critical task and requires a delicate balance. Holding onto too much stock ties up valuable capital, hindering cash flow and flexibility. Conversely, running out of critical supplies can bring production screeching to a halt, leading to missed deadlines and unhappy customers. This is where lean manufacturing and just-in-time (JIT) inventory management come in, offering strategies to optimize this balancing act.

Product Data Enhancements APRIL 2024 monthly data update New Brands duMONT CNC Gmauvais Hassay Savage Magafor User Upload – NEW

In the high-octane world of manufacturing, every cog needs to be turning smoothly for peak performance. While the focus often falls on the latest machinery and automation, there’s an unsung hero behind the scenes: accurate tool data. This seemingly mundane information holds immense power, and with the rise of Artificial Intelligence (AI), its importance is only going to grow.