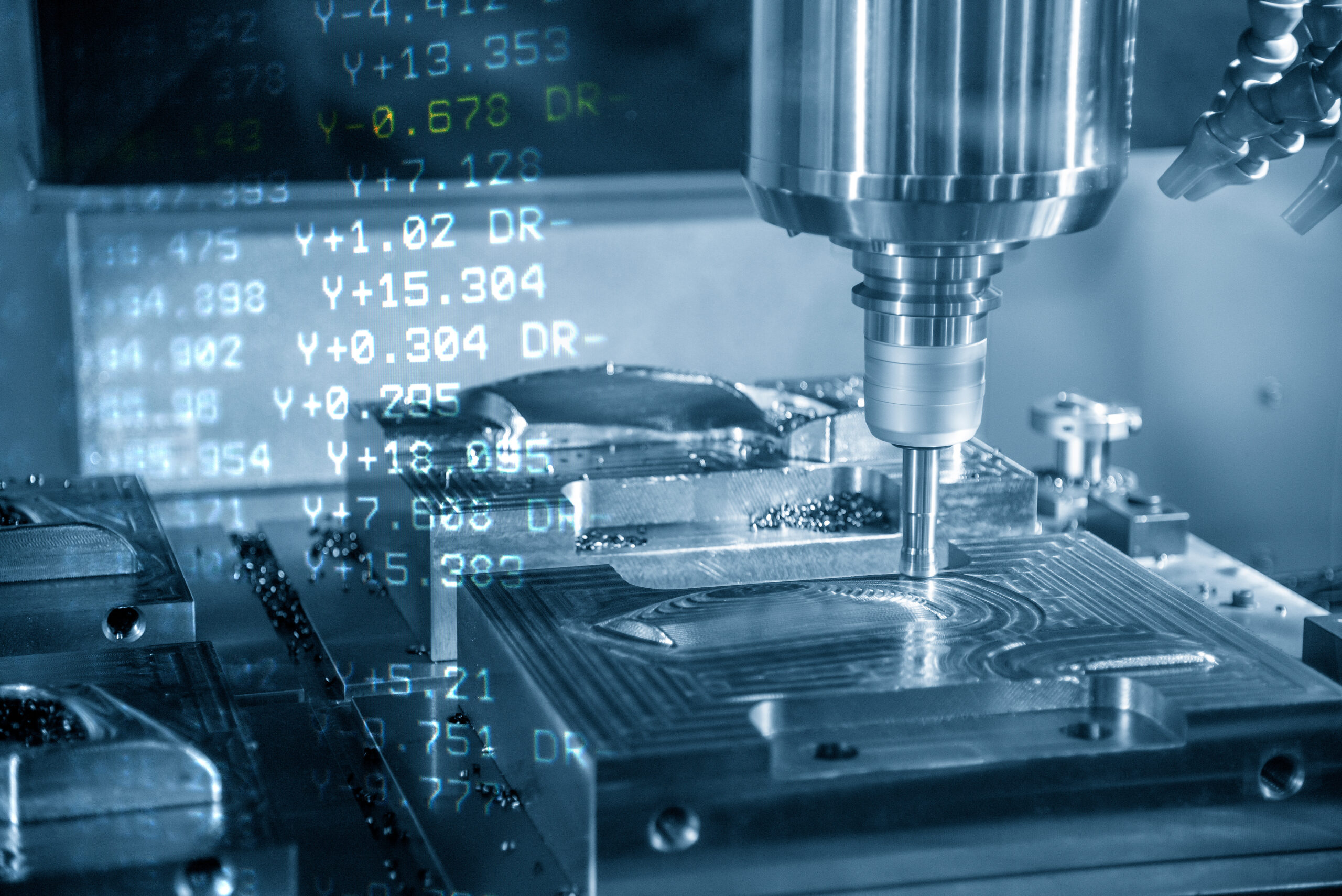

Why Continuity is King in Modern Machining

In the fast-paced world of machining, where precision and efficiency reign supreme, the concept of continuity is no longer a luxury – it’s a fundamental pillar of success. Building upon the ideas discussed in our previous article, “Of Knowledge Management,” we now delve deeper into the critical role of seamless continuity, particularly concerning work processes and the invaluable information that fuels them.