Unleashing the Power of Browsing:

MachiningCloud is more than just a search tool; it is a gateway to a vast repository of machining data and resources. With a user-friendly interface, it provides seamless navigation through an extensive collection of digital catalogs, cutting tool data, 3D models, and much more. By harnessing the power of browsing, machinists, CNC programmers and tooling specialists gain unprecedented access to a world of possibilities, opening doors to enhanced productivity, informed decision-making, and ultimately, superior outcomes.

Efficiency at Your Fingertips:

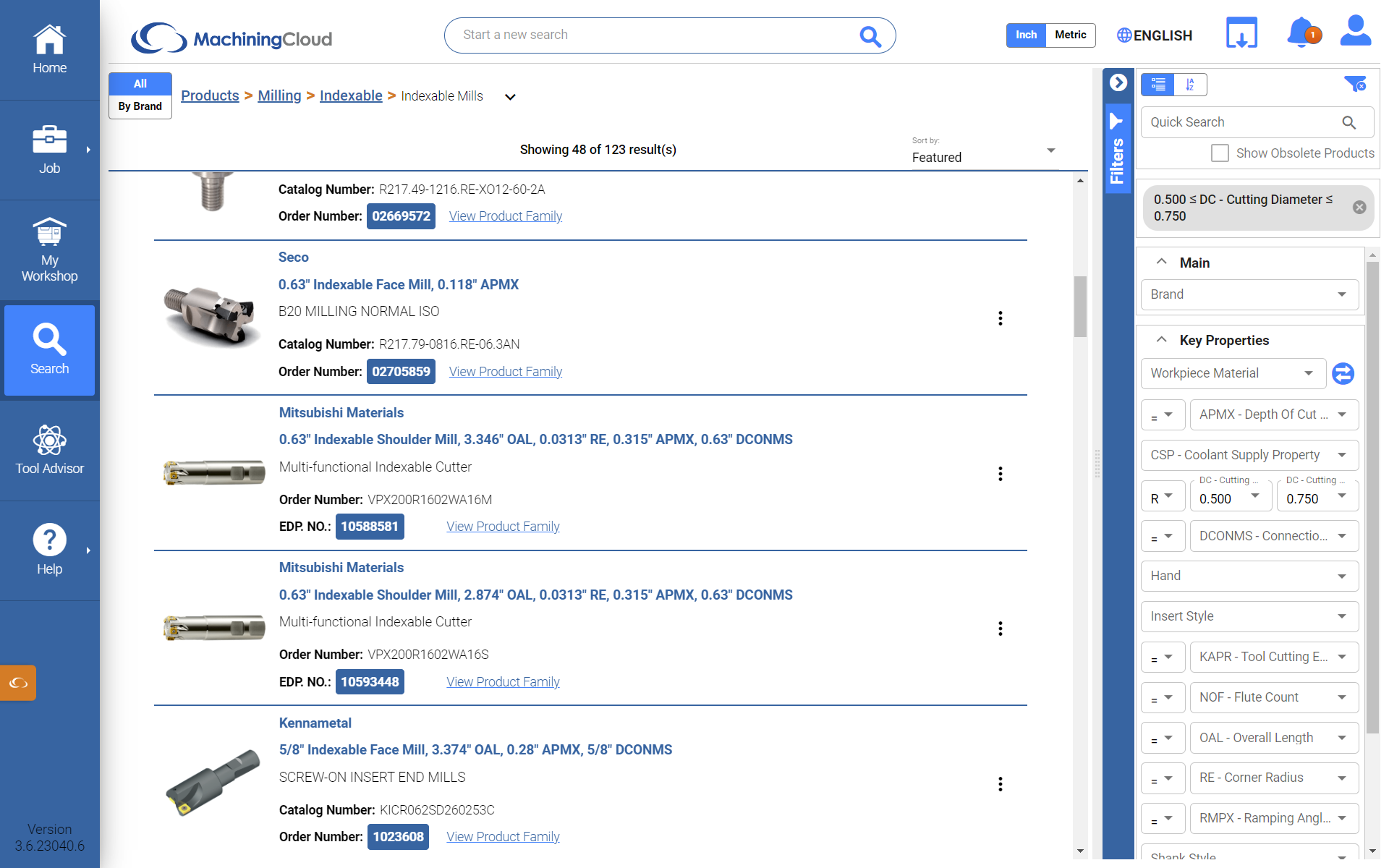

Gone are the days of cumbersome physical catalogs and tedious manual searches. MachiningCloud enables users to swiftly navigate through a comprehensive library of digital catalogs from leading cutting tool manufacturers. The intuitive interface allows users to effortlessly explore different categories, filter search results, and compare specifications. By streamlining the information retrieval process, browsing saves valuable time and eliminates the frustration associated with traditional catalog browsing methods, or bouncing around multiple websites.

Empowering Informed Decision-Making:

In machining, selecting the right tool or component is critical to achieving optimal results. MachiningCloud provides users with a wealth of data and insights to make informed decisions. With detailed technical specifications, performance ratings, pricing information, and availability indicators readily available, professionals can confidently assess and compare various options. This empowers them to select the most suitable tools and components that align with their project requirements, minimizing errors and maximizing efficiency.

Visualization and Collaboration:

One of the standout features of MachiningCloud is its seamless integration with 3D models by allowing users to view and interact with digital representations of cutting tools, workholding and tooling assemblies. This visual aspect enhances understanding and enables designers and machinists to align their vision effectively. With this level of clarity, potential issues can be identified and resolved early in the process, avoiding costly mistakes down the line. For instance, MachiningCloud users can quickly and easily find out if a given tool will fit properly in any given toolholder, even if they are from different brands.

Staying Ahead of the Curve:

As an industry thought leader, MachiningCloud constantly evolves to meet the ever-changing needs of the machining community. The browsing feature is continuously updated with the latest catalogs, cutting tool data, and technological advancements, ensuring that professionals have access to the most up-to-date information. By staying ahead of the curve, MachiningCloud empowers users to explore new avenues, embrace innovation, and gain a competitive edge in the dynamic landscape of precision manufacturing.

MachiningCloud has revolutionized the way machinists, CNC programmers and tooling specialists approach their work. By harnessing the power of digital catalogs, comprehensive data, and intuitive navigation, this browsing feature streamlines processes, enhances decision-making, and fosters collaboration. As the industry marches towards increased automation and digitalization, MachiningCloud remains at the forefront, empowering professionals to unlock their full potential and achieve exceptional results. Embrace the power of browsing with MachiningCloud and experience a new era of efficiency and precision in machining.